SUGAR INDUSTRY

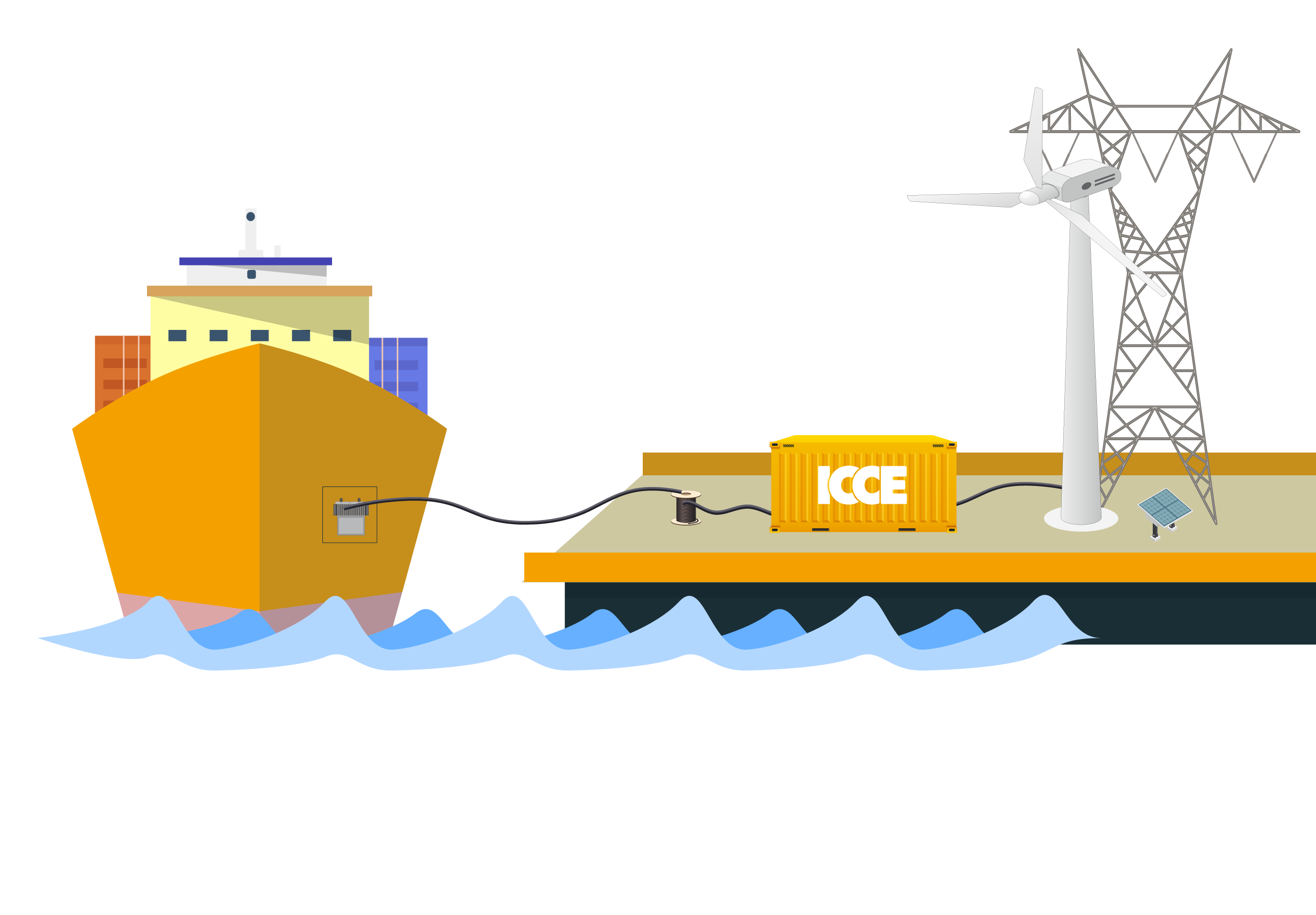

We are specialists in sugar processing. A well-coordinated team of electrical, automation, and technology engineers dedicated to providing advanced automation solutions. Our team has over 30 years of common experience. Hundreds of projects realized ensure full automation integration into sugar production.

Our field of expertise encompasses the modernization of existing and outdated plants to the development of completely new plants. We automate single processes to plant-wide systems. We can integrate each process into a unique system for monitoring and control of the factory.

With implemented solutions in more than 30 factories throughout the world, we are recognized for our commitment to engineering excellence. We cover complete processes in the:

- Sugar beet/cane processing plants

- Chromatography plants

- Ethanol plants

PROJECT:

Kristall Kirsanov is one of the biggest sugar processing plants in the world. For the further extension of their production capacities, they decided to build a complete new facility, containing every technological unit needed for sugar production.

The investment included construction of the new facility with more than 30 subsystems such as:

- Beet receipt & washing

- Diffusion

- Beet slicing

- Lime kiln furnace

- Crystallization & cooking

The systems were provided by different technology providers causing the problem with integration of different technological units into one control system.

Our expertise and experience with similar projects, recommended us to solve the issue with integration of technological units into the control system. Our solution included a comprehensive control system with all technological units integrated. Furthermore, we provided a complementary user-friendly software for process monitoring and control on the factory level.

The new facility after the automation can process 20,000 t/day sugar beet.

OUR CONTRACT:

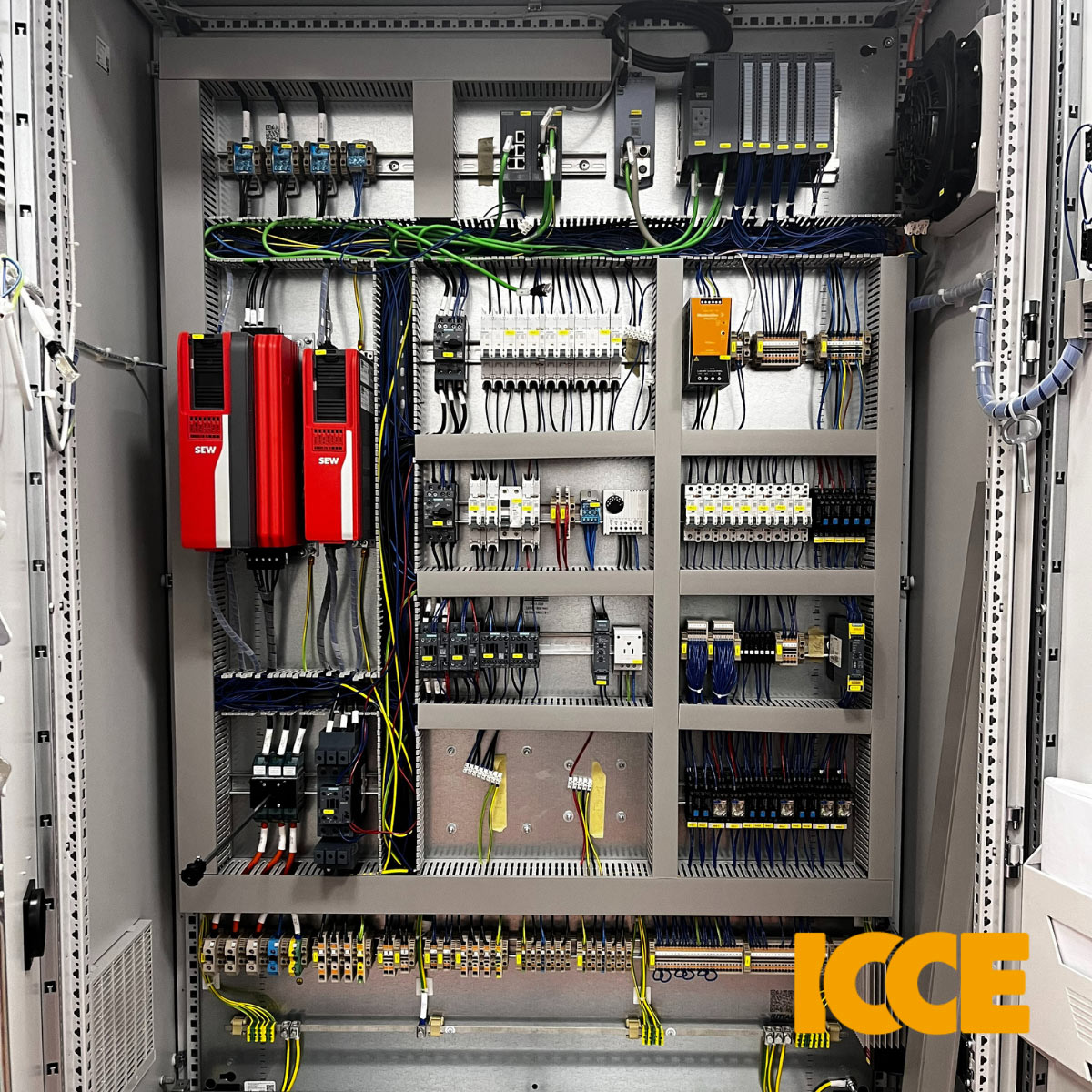

- Electric Design

- Control System

- PLC&SCADA Software Development

- Commissioning & Start up

PROJECT:

RUSAGRO was considering the modernization of their Sugar Processing Plant Znamensky. The equipment they were using was not aligned with their needs.

The existing system was not good enough to support operations, and the problem with maintenance and spare parts. We were entrusted to change the automation system of the chromatograpy plant inside Znamensky sugar plant.

This automation project included switching on the new, modern DCS system. The main challenge with this project was to minimize the period while the plant is out of service to few weeks during the modernization activities.

OUR CONTRACT:

- Engineering

- Electrical Design

- Control System

- PLC&SCADA Software development

- Installation Supervision

- Commissioning & Start-up

PROJECT:

Rusagro is one of the leaders in the sugar processing, which provides general management and centralized coordination of the activities of subsidiary sugar companies.

Rusagro was considering the modernization of their Sugar Processing Plant Chernyanski Saharni Zavod. This project included gradual automation and electrical equipment from 2017 to 2019.

The fist phase was building of Chromatography plant. In the next stages factory was upgraded with: Diffusion Line, Pumping Stations (Heating Station) and Sugar Silo with capacity of 50,000 t.

The completion of the project resulted in:

- Plant’s capacity that allows processing of 100% of molasses produced on six Rusagro’s sugar plants, establishing the factory as the leader in molasses processing

- Product extract contributes to production with extra c. 70 thousand tonnes of sugar per year

OUR CONTRACT:

- Engineering

- Electrical Design

- Motor Control Center

- Control System

- PLC&SCADA Software development

- Commissiong & Start-up

PROJECT:

Sucden, one of the leaders in sugar production, undertook the gradual reconstruction and modernization of the production plant. The reconstruction project took place in the period from 2005 to 2016. For the automation and electrical equipment, Sucden chose us as a realiable partner for over 20 years.

In various departments certain process lines were replaced and new process lines were gradually added. The entire plant is fully automated resulting:

- The capacity increased from 5,500t to 12,000t of beet per day

- Highest final product quality that meets strict criteria of Pepsi and Coca Cola

- The plant is operative during the whole year, not only during the season. In off-season plant processes raw sugar, producing the final product (sugar) in the same quality

OUR CONTRACT:

- Electrical Design

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Commissioning & Start-up

Kristall Kirsanov is one of the biggest sugar processing plants in the world. For the further extension of their production capacities, they decided to build a complete new facility, containing every technological unit needed for sugar production.

The investment included construction of the new facility with more than 30 subsystems such as:

- Beet receipt & washing

- Diffusion

- Beet slicing

- Lime kiln furnace

- Crystallization & cooking

OUR CONTRACT:

The systems were provided by different technology providers causing the problem with integration of different technological units into one control system.

Our expertise and experience with similar projects, recommended us to solve the issue with integration of technological units into the control system. Our solution included a comprehensive control system with all technological units integrated. Furthermore, we provided a complementary user-friendly software for process monitoring and control on the factory level.

The new facility after the automation can process 20,000 t/day sugar beet.

- Electric Design

- Control System

- PLC&SCADA Software Development

- Commissioning & Start up

RUSAGRO was considering the modernization of their Sugar Processing Plant Znamensky. The equipment they were using was not aligned with their needs.

The existing system was not good enough to support operations, and the problem with maintenance and spare parts. We were entrusted to change the automation system of the chromatograpy plant inside Znamensky sugar plant.

This automation project included switching on the new, modern DCS system. The main challenge with this project was to minimize the period while the plant is out of service to few weeks during the modernization activities.

OUR CONTRACT:

- Engineering

- Electrical Design

- Control System

- PLC&SCADA Software development

- Installation Supervision

- Commissioning & Start-up

Rusagro is one of the leaders in the sugar processing, which provides general management and centralized coordination of the activities of subsidiary sugar companies.

Rusagro was considering the modernization of their Sugar Processing Plant Chernyanski Saharni Zavod. This project included gradual automation and electrical equipment from 2017 to 2019.

The fist phase was building of Chromatography plant. In the next stages factory was upgraded with: Diffusion Line, Pumping Stations (Heating Station) and Sugar Silo with capacity of 50,000 t.

The completion of the project resulted in:

- Plant’s capacity that allows processing of 100% of molasses produced on six Rusagro’s sugar plants, establishing the factory as the leader in molasses processing

- Product extract contributes to production with extra c. 70 thousand tonnes of sugar per year

OUR CONTRACT:

- Engineering

- Electrical Design

- Motor Control Center

- Control System

- PLC&SCADA Software development

- Commissiong & Start-up

“Dobrinskiy saharniy zavod” (RUSSIA) requested the reconstruction of their entire sugar factory.

Sucden, one of the leaders in sugar production, undertook the gradual reconstruction and modernization of the production plant. The reconstruction project took place in the period from 2005 to 2016. For the automation and electrical equipment, Sucden chose us as a realiable partner for over 20 years.

In various departments certain process lines were replaced and new process lines were gradually added. The entire plant is fully automated resulting:

- The capacity increased from 5500t to 12000t of beet per day

- Highest final product quality that meets strict criteria of Pepsi and Coca Cola

- The plant is operative during the whole year, not only during the season. In off-season plant processes raw sugar, producing the final product (sugar) in the same quality

OUR CONTRACT:

- Electrical Design

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Commissioning & Start-up

Let's talk about Solutions.

NEWS