BULK MATERIAL HANDLING

Bulk material handling encompasses equipment employed in the handling of materials such as grain, fertilizers, coal, iron ore, pet coke, cement, salt, and such. Numerous industrial facilities such as mines, ports, and power & steel plants, require solutions for handling the bulk material used in their day-to-day business.

We have more than three decades of experience providing electrical and automation systems for bulk material handling. Our systems are highly adaptable and tailored to meet the specific needs of our clients.

Our portfolio covers solutions from single processes to plant-wide systems covering any capacity from 100 to 12,000 tons per hour:

- Storage (silo, longitudinal, circular)

- Conveying

- Stacking/Reclaiming

- Excavating

- Loading/Unloading (ship, truck, train)

- Dosing, weighing, mixing

PROJECT:

The port of Ashdod requested a delivery of a continuous ship unloader, that would be able to unload grain from Panamax-size ships to either trucks or silos.

The complete mechanical part of the machine was designed by the company Bedeschi, while ICCE was responsible for the development of the electrical system.

The investment included the delivery of the following equipment:

- Ship unloader for Grain 1,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

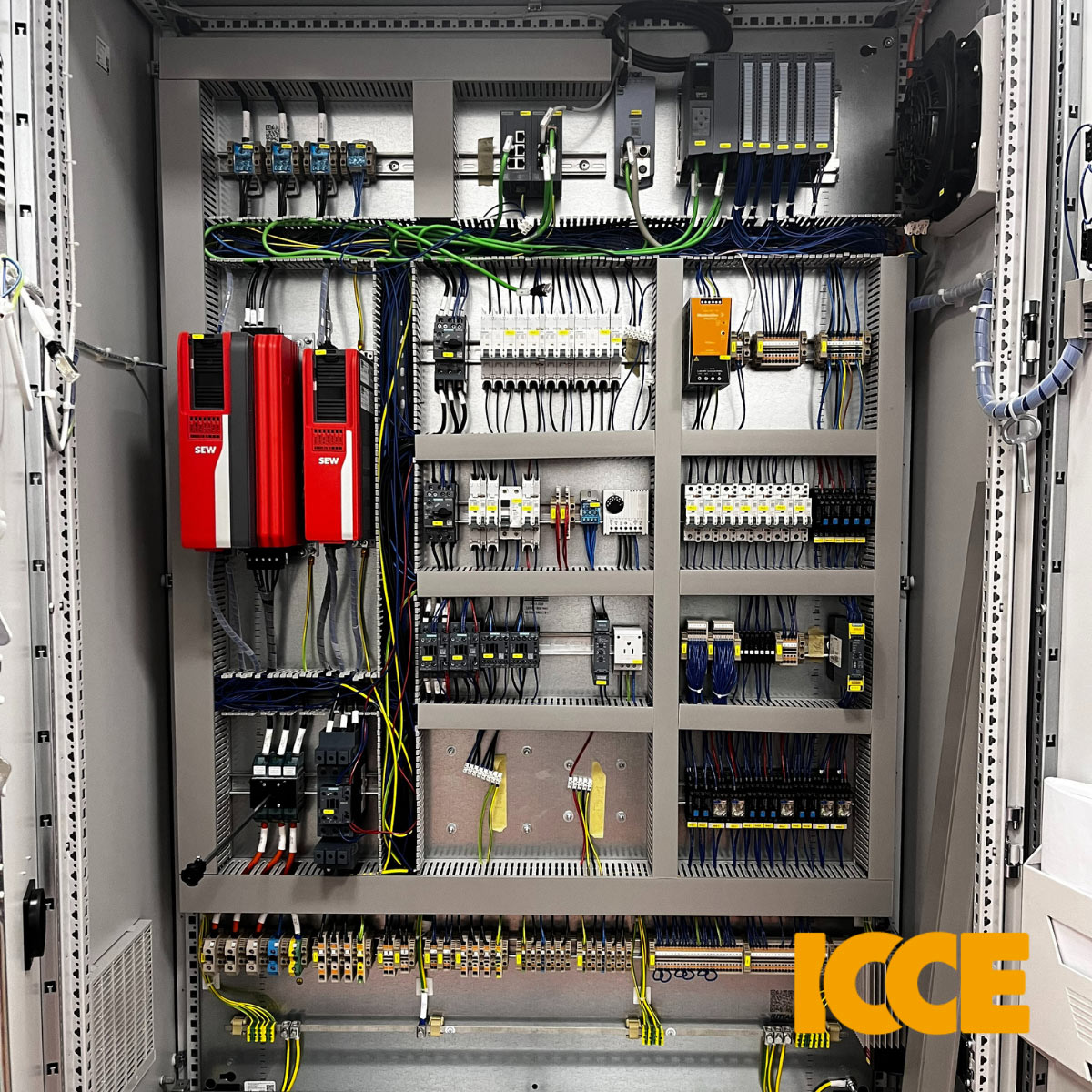

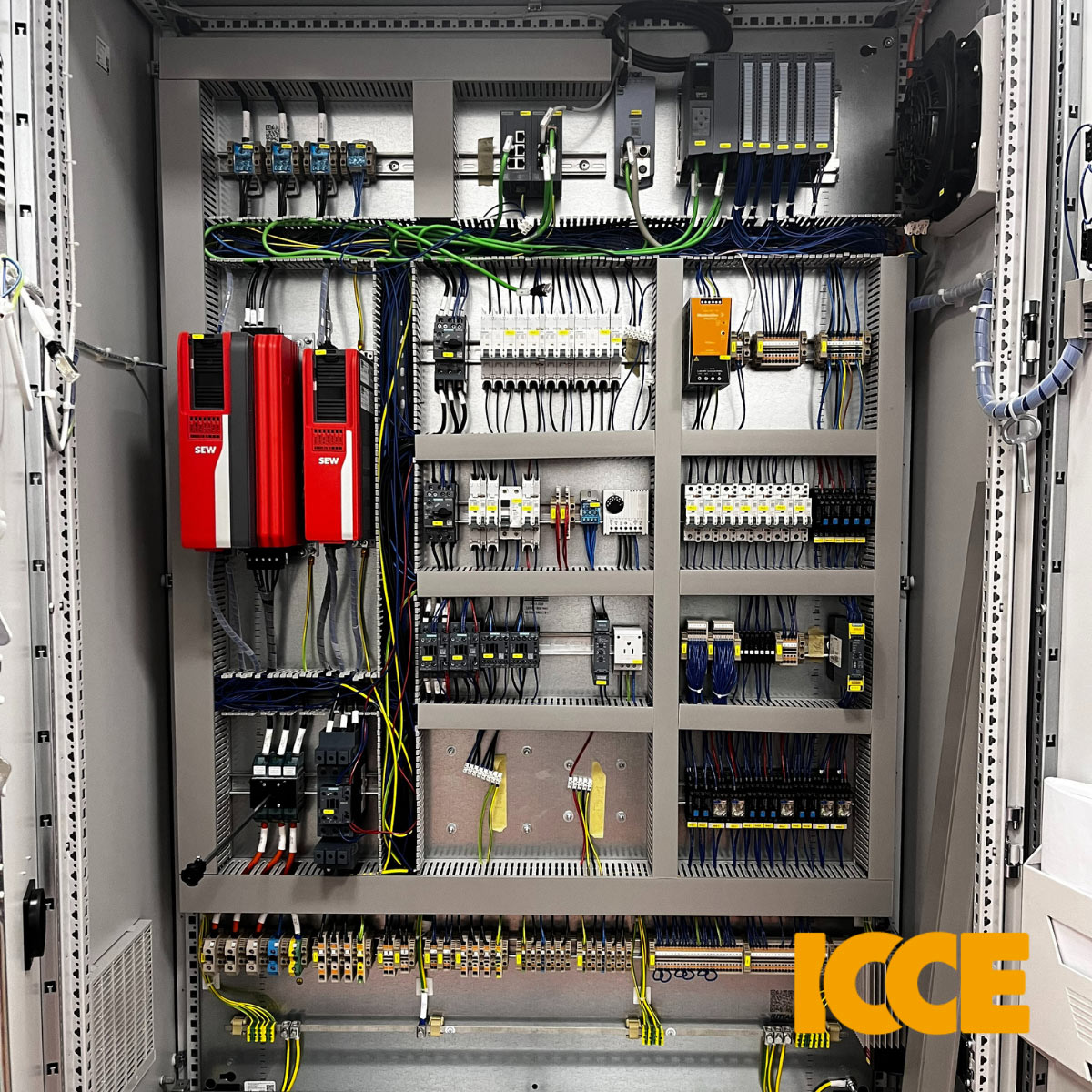

- Motor Control Center

- Control System

- PLC & SCADA Software Development

- HMI Programing

- Commissioning & Start-Up

PROJECT:

OTEKO-Portservice LLC, founded in 2006, is a prominent operator in both cargo handling and railway transportation.Oteko-Portservice invested more than $1B in their coal terminal in Taman. In 2019, they have initiated a second project phase of their coal terminal. The total capacity of the second phase coal terminal is 60 million tonnes per year.

ICCE was involved in the development of the electrical systems that allows handling of 8,000 t/h of coal. The investment included the delivery of the following equipment:

- Conveyor systems: 2 x 8,000 t/h

- The total length of conveyors: 18,000 m

OUR CONTRACT:

- Engineering

- Electrical Design

- Medium & Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Ehouse

- Instrumentation

- Installation Supervision

- Commissioning & Start-up

PROJECT:

Kernel LLC, the biggest producer of vegetable oil in the world, was looking to expand its handling capabilities of grain, in the port of Chornomorsk.

Company Bedeschi, who won the project, was looking for a reliable partner who would be able to deliver a complete electrical & automation system in under 6 months.

The investment included the delivery of the following equipment:

- Two Ship Loaders with capacity 2,200 t/h each

- Two Tripper

- Gallery belt conveyors 2,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC Software Development

- HMI Programing

- Ehouse

- Operator Cabin

- Cable & Cable trays

- Instrumentation

- General Installations

- Installation supervision

- Commissioning & Start-Up

PROJECT:

Taman Bulk Cargo Terminal (TTNG), situated at the Black Sea, is a major port accommodating a diverse range of vessels. In 2011 grain terminal Taman invested in its capacity extension.

Today, Taman grain terminal features 16 silos, with a storage capacity of 120,000 tonnes. Its production facilities enable the daily unloading of 24,000 tonnes of agricultural products from trucks and loading of 36,000 tonnes into ships.

One of the main project challenges were conveyor belts, reaching 2km deep into the sea. ICCE developed solution that was unique in both energetic and automation aspect. The complete equipment was contained in the specialized Ehouses, adjusted for the seawater environment.

The capacity extension of the Grain Terminal Taman included the following equipment:

- Total Silo Capacity 120,000 t

- Handling Capacity 2x 1,500 t/h

- Ship Loading Capacity 2x 1,500 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Commissioning and Start-up

- Dedusting and Fumigation System

PROJECT: Bedeschi SpA, Israel 2021

PROJECT:

The port of Ashdod requested a delivery of a continuous ship unloader, that would be able to unload grain from Panamax-size ships to either trucks or silos.

The complete mechanical part of the machine was designed by the company Bedeschi, while ICCE was responsible for the development of the electrical system.

The investment included the delivery of the following equipment:

- Ship unloader for Grain 1,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Motor Control Center

- Control System

- PLC & SCADA Software Development

- HMI Programing

- Commissioning & Start-Up

PROJECT:

OTEKO-Portservice LLC, founded in 2006, is a prominent operator in both cargo handling and railway transportation.Oteko-Portservice invested more than $1B in their coal terminal in Taman. In 2019, they have initiated a second project phase of their coal terminal. The total capacity of the second phase coal terminal is 60 million tonnes per year.

ICCE was involved in the development of the electrical systems that allows handling of 8,000 t/h of coal. The investment included the delivery of the following equipment:

- Conveyor systems: 2 x 8,000 t/h

- The total length of conveyors: 18,000 m

OUR CONTRACT:

- Engineering

- Electrical Design

- Medium & Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Ehouse

- Instrumentation

- Installation Supervision

- Commissioning & Start-up

PROJECT:

Kernel LLC, the biggest producer of vegetable oil in the world, was looking to expand its handling capabilities of grain, in the port of Chornomorsk.

Company Bedeschi, who won the project, was looking for a reliable partner who would be able to deliver a complete electrical & automation system in under 6 months.

The investment included the delivery of the following equipment:

- Two Ship Loaders with capacity 2,200 t/h each

- Two Tripper

- Gallery belt conveyors 2,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC Software Development

- HMI Programing

- Ehouse

- Operator Cabin

- Cable & Cable trays

- Instrumentation

- General Installations

- Installation supervision

- Commissioning & Start-Up

PROJECT:

Taman Bulk Cargo Terminal (TTNG), situated at the Black Sea, is a major port accommodating a diverse range of vessels. In 2011 grain terminal Taman invested in its capacity extension.

Today, Taman grain terminal features 16 silos, with a storage capacity of 120,000 tonnes. Its production facilities enable the daily unloading of 24,000 tonnes of agricultural products from trucks and loading of 36,000 tonnes into ships.

One of the main project challenges were conveyor belts, reaching 2km deep into the sea. ICCE developed solution that was unique in both energetic and automation aspect. The complete equipment was contained in the specialized Ehouses, adjusted for the seawater environment.

The capacity extension of the Grain Terminal Taman included the following equipment:

- Total Silo Capacity 120,000 t

- Handling Capacity 2x 1,500 t/h

- Ship Loading Capacity 2x 1,500 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Commissioning and Start-up

- Dedusting and Fumigation System

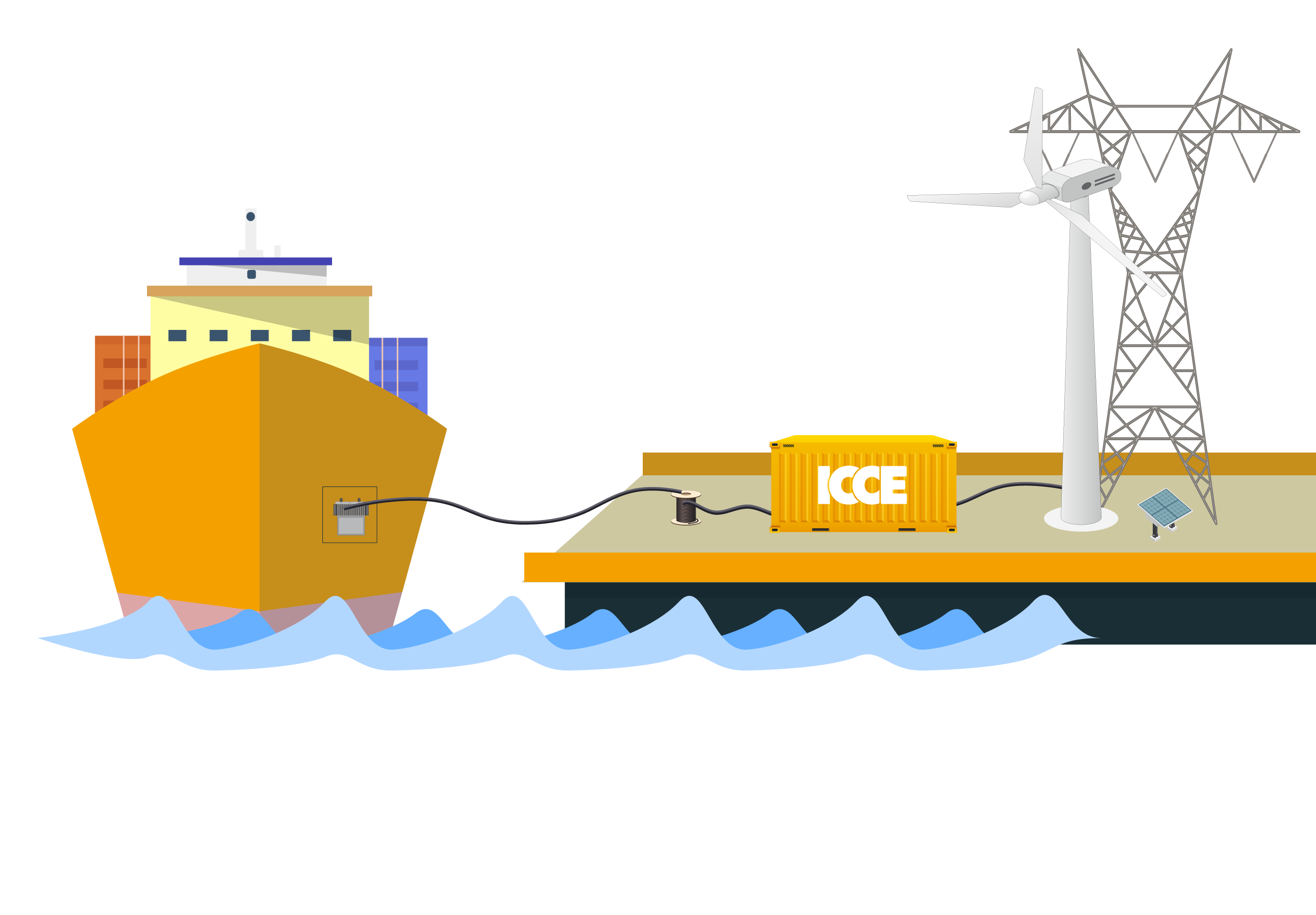

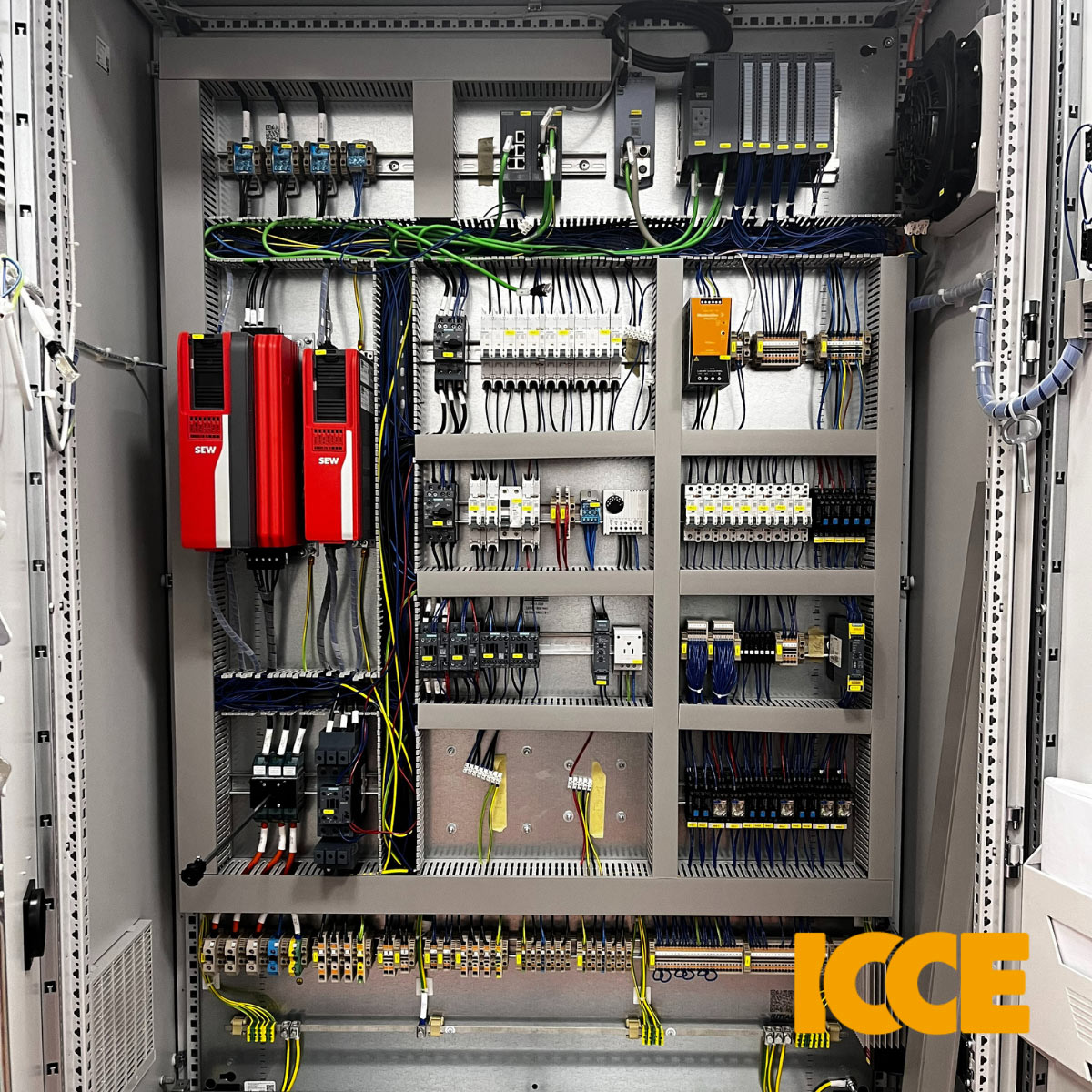

The port of Ashdod is one of the three Israeli’s largest cargo ports. The port requested a delivery of a continuous ship unloader, that would be able to unload grain from Panamax-size ships to either trucks or silos.

The complete mechanical part of the machine was designed by the company Bedeschi, while ICCE was responsible for the development of the electrical system.

The investment included the delivery of the following equipment:

- Ship unloader for Grain 1,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Motor Control Center

- Control System

- PLC & SCADA Software Development

- HMI Programing

- Commissioning & Start-Up

OTEKO-Portservice LLC, founded in 2006, is a prominent operator in both cargo handling and railway transportation.Oteko-Portservice invested more than $1B in their coal terminal in Taman. Making it the biggest export terminal in Russia. In 2019, they have initiated a second project phase of their coal terminal. The total capacity of the second phase coal terminal is 60 million tonnes per year.

ICCE was involved in the development of the electrical systems that allows handling of 8000 t/h of coal. The handling equipment included:

The equipment includes:

- Conveyor systems: 2 x 8000t/h

- The total length of conveyors: 18000m

OUR CONTRACT:

- Engineering

- Electrical Design

- Medium & Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Ehouse

- Instrumentation

- Installation Supervision

- Commissioning & Start-up

Kernel LLC, the biggest producer of vegetable oil in the world, was looking to expand its handling capabilities of grain, in the port of Chornomorsk.

Company Bedeschi, who won the project, was looking for a reliable partner who would be able to deliver a complete electrical & automation system in under 6 months.

The investment included the delivery of the following equipment:

- Two Ship Loaders with capacity 2,200 t/h each

- Two Tripper

- Gallery belt conveyors 2,200 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC Software Development

- HMI Programing

- Ehouse

- Operator Cabin

- Cable & Cable trays

- Instrumentation

- General Installations

- Installation supervision

- Commissioning & Start-Up

PROJECT: TAMAN

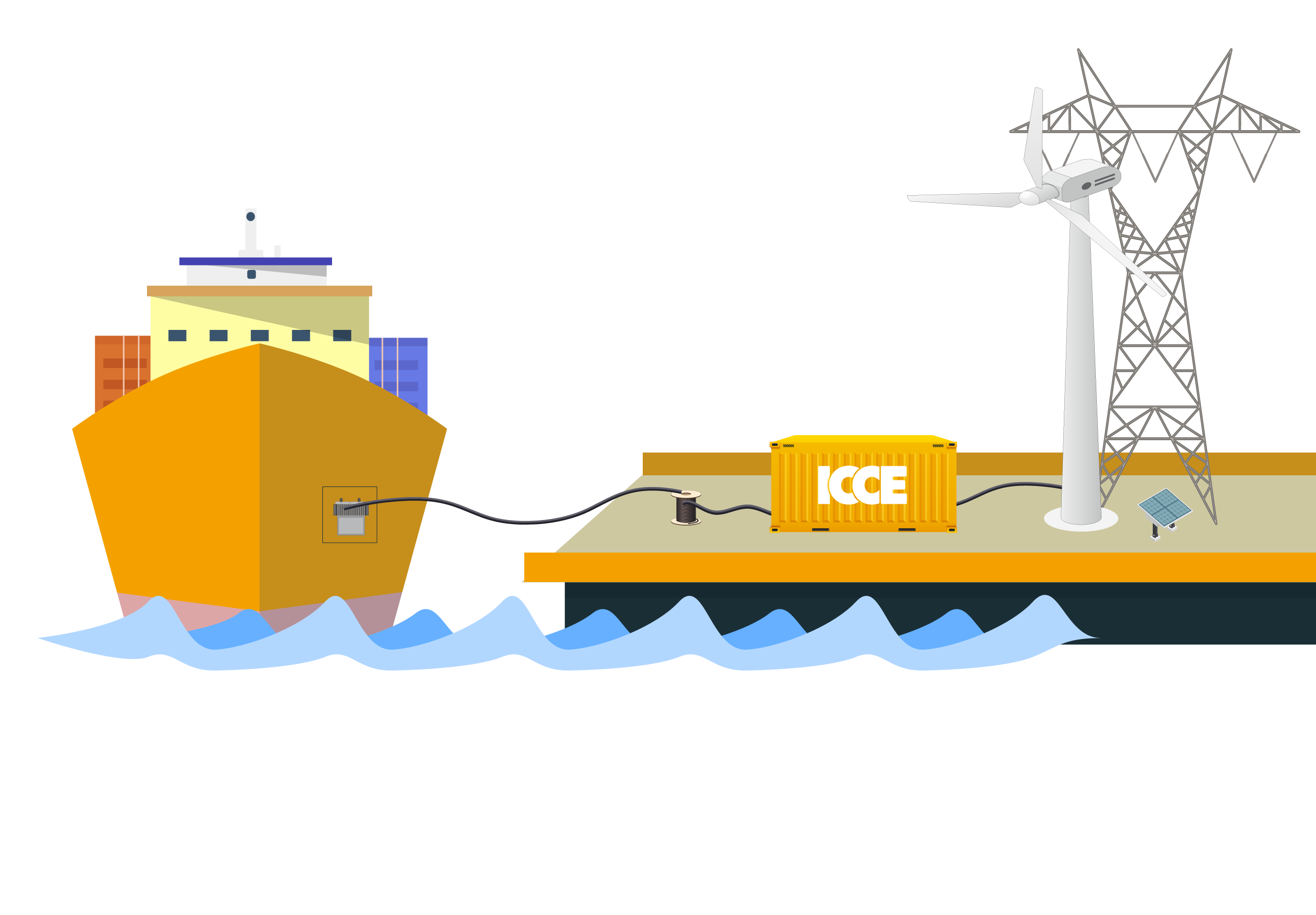

Taman Bulk Cargo Terminal (TTNG), situated at the Black Sea in Russia, is a major port accommodating a diverse range of vessels. In 2011 grain terminal Taman invested in its capacity extension.

Today, Taman grain terminal features 16 silos, with a storage capacity of 120,000 tonnes. Its production facilities enable the daily unloading of 24,000 tonnes of agricultural products from trucks and loading of 36,000 tonnes into ships.

One of the main project challenges were conveyor belts, reaching 2km deep into the sea. ICCE developed solution that was unique in both energetic and automation aspect. The complete equipment was contained in the specialized Ehouses, adjusted for the seawater environment.

The capacity extension of the Grain Terminal Taman included the following equipment:

- Total Silo Capacity 120,000t

- Handling Capacity 2x 1,500 t/h

- Ship Loading Capacity 2x 1,500 t/h

OUR CONTRACT:

- Engineering

- Electrical Design

- Low Voltage

- Motor Control Center

- Control System

- PLC&SCADA Software Development

- Commissioning and Start-up

- Dedusting and Fumigation System

Let's talk about Solutions.

NEWS